Henkel's Acheson® brand makes specialty coatings primarily for friction reduction, squeak reduction, release, abrasion & wear resistance, conductivity, and shielding. They are most notably known for their Emralon® series coatings which have recently been renamed with BONDERITE® and LOCTITE® trade names.

Coating Descriptions

Bonderite S-FN 310A & Bonderite S-OT 310B

Two part, phenolic resin-bonded PTFE coating and lubricant, Emralon 310 provides a low coefficient of friction while exhibiting excellent surface adhesion, corrosion resistance, and release properties. With a low cure temperature (300°F), Bonderite S-FN 310A & Bonderite S-OT 310B can be used in many applications where conventional PTFE coatings cannot even be considered. Before being acquired by Henkel, Bonderite S-FN 310A Acheson and Bonderite S-OT 310B Acheson were called Acheson Emralon 310.

Bonderite S-FN 333

With a longer wear life than pure PTFE, superior chemical resistance and the ability to be repaired without moving the existing coating, Bonderite S-FN 333 is a resin-bonded lubricant designed to provide dry film lubrication and release properties for any variety of applications. Its low coefficient of friction, hardness, adhesion, resiliency, and cure conditions allow the application of Bonderite S-FN 333 in a multitude of places where pure PTFE coatings are unsuitable. Before being acquired by Henkel, Bonderite S-FN 333 was called Acheson’s Emralon 333.

Bonderite S-FN 334

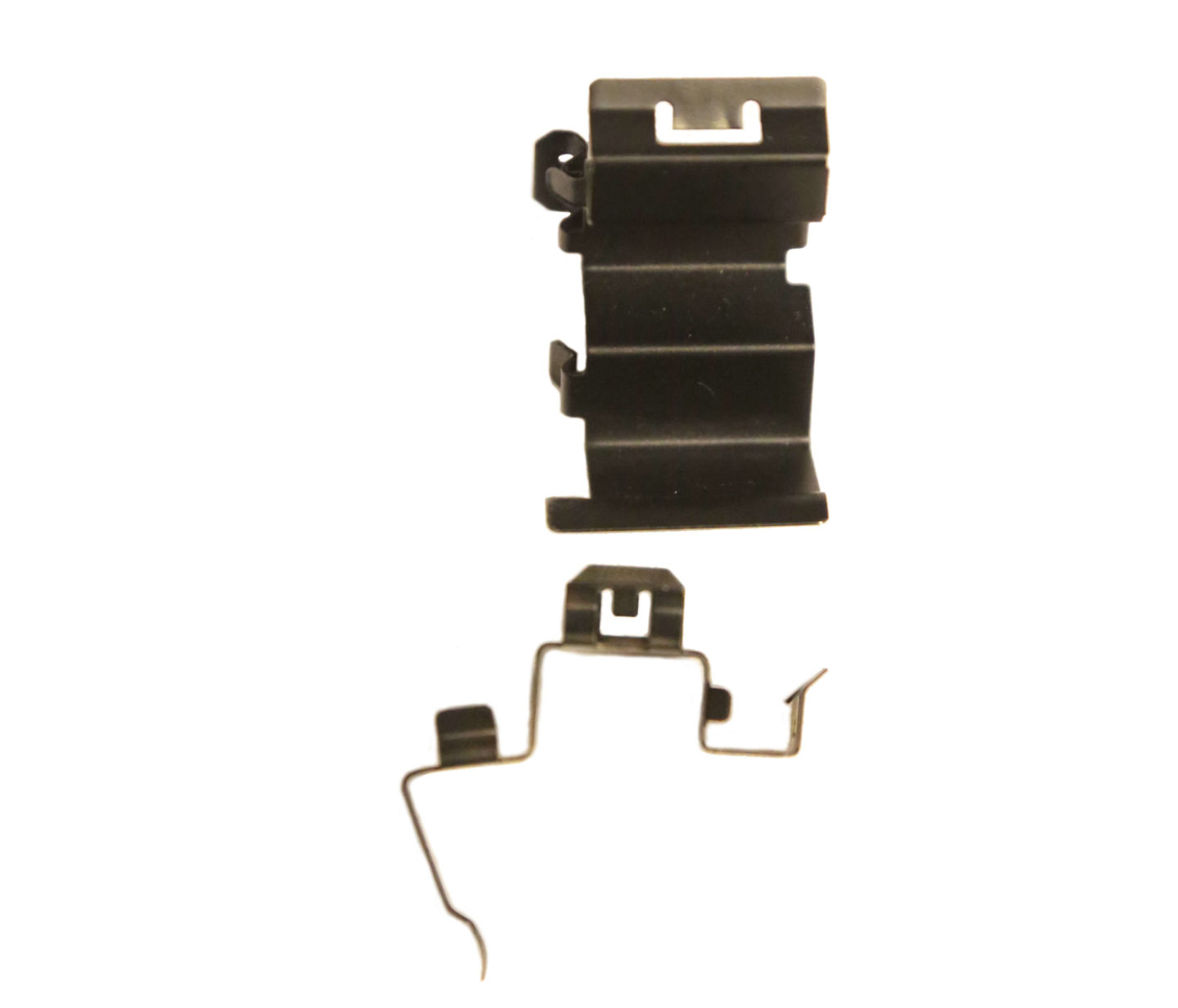

Particularly suitable for the lubricant coating of automotive components due to its superior physical properties, 500°F service temperature and excellent salt spray resistance, Bonderite S-FN 334 is a resin-bonded dry film lubricant and release coating that also exhibits exceptional abrasion resistant qualities. Before being acquired by Henkel, Bonderite S-FN 334 was known as Acheson’s Emralon 334.

Loctite EDAG GP 1904 E&C

A dispersion of PTFE and graphite in a thermosetting binder, Loctite EDAG GP 1904 E&C produces a low friction coating with excellent resistance to coating and solvents. Because of the wide range of cure temperatures, Loctite EDAG GP 1904 E&C can be used on a variety of substrate types. Before being acquired by Henkel, Loctite EDAG GP 1904 E&C was known as Acheson’s GP 1904.

Bonderite S-FN M 250

A compound of highly refined molybdenum disulfide and processed micro-graphite, Bonderite S-FN M 250 reduces corrosion, abrasion, flexing and impact, all while forming a clean, dry, long –wearing film that provides excellent extreme pressure lubrication. This coating is particularly effective for components that inaccessible or impractical to service after assembly. Before being acquired by Henkel, Bonderite S-FN M 250 was known as Acheson’s Molydag 250.

Molydag 254

A synergistic combination of molybdenum disulfide and other lubricants dispersed in an epoxy resin solution, Molydag 254 provides lifetime lubrication and good corrosion resistance for components that are inaccessible after assembly, but must continue to function reliably.

DECC is not licensed to sell individual or packaged coatings.

DECC is your resource for the application of the coatings listed for Henkel®